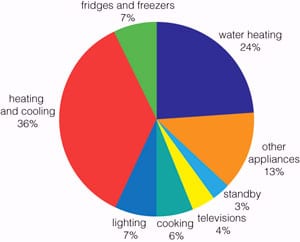

Heating and cooling currently account for 36% of Australia’s household energy consumption and shelter accounts for 29% our overall footprint per capita.

Hemp Masonry is thermally efficient housing that is sourced from renewable resources offers a solution.

Hemp Masonry buildings achieve exceptional thermal comfort with minimal heating and cooling because the material:

- is highly insulative

- has light thermal mass

- is breathable

- has excellent hygro-thermal performance managing humidity in buildings exceptionally well and avoiding the formation of moulds

1. LOW EMBODIED ENERGY IN THE MATERIALS, PLUS REDUCED ENERGY USE AND COSTS

A 2 year monitoring program on renewable houses in the UK found that the “insulating properties of hemcrete mean that heating plant can be reduced in size, reducing corresponding energy consumption and carbon emissions, which could be in the range between 50% and 80% lower than in buildings with conventional brick and block construction, insulated to the same U-value as the hemcrete construction.” (Proceedings of the 1st International Conference on Zero Carbon Buildings Today and in the Future, Birmingham City University, 11-12 September 2014.

In an early comparative analysis of identical brick and hemp homes in the UK, in the hemp home a desired temperature of 21º C was reached after the heating had been on for around 2 hours, and the building thermostatically maintained that temperature for the remainder of the heating period.In the brick house, however, a maximum temperature of 20º C is only reached after the heating has been on for approximately 4 hours. Therefore, in the morning, when the heating is on for a shorter period of time, the desired temperature is never reached in the brick house. (Centre for Alternative Technology, Wales)

Adnam’s Brewery and Distribution Centre in Suffolk, UK (2006) While building the 4400 sq m building with 500mm thick hemp walls raised the cost of the 5.8 million pound project by 40,000 pounds, this spending allowed Adnam’s to avoid installing a 40,000 pound cooling system. There are no ongoing costs to run a cooling system. The warehouse maintains a 12º – 14ºC environment. More than 500 tonnes of CO2 emissions were avoided compared with using conventional materials.

2. SLOW PHASE CHANGE MATERIALS

When external Hemp Masonry walls are exposed to the sun they heat up very little, and when the outside temperature drops they are also able to release heat to balance the difference in temperature between the inside and outside. (Perier 2001) These properties were also confirmed by the BRE’ s tests (2001) in Haverhill.

3. EMISSIONS REDUCTION AND CARBON STORAGE

Hemp buildings store the carbon that has been harvested through the farming of the hemp in the building envelope. The thickness of the walls and whether or not there is also subfloor and roofing insulation all influence the amount of carbon stored. The lime in the AHMC Binder draws in further carbon dioxide as it slowly achieves a full cure. This combination more than balances out the energy emissions in making the AHMC Binder.

“Having a low impact, carbon-negative, sustainable form of construction that can be used in volume house building or even multi-storey office blocks, factories and warehouses is an exciting development that provides a genuine solution to demands for zero-carbon construction.” (Rachel Bevan & Prof. Tom Woolley, Hemp lime Construction, A Guide to Building with Hemp Lime Composites, BRE Press, UK)